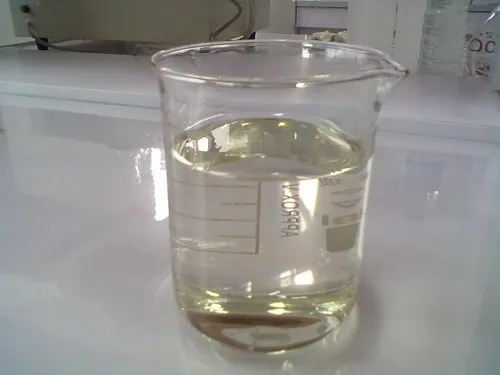

Refined Glycerine 99.7% Min USP 43 (Flexi)

|

IUPAC Name |

: Propane-1,2,3-triol |

|

Cas Number |

: 56-81-5 |

|

HS Code |

: 2905.45.00 |

|

Formula |

: C3H8O3 |

Basic Info

|

Appearance Name |

: Clear Colorless Liquid |

|

Common Names |

: 1,2,3-propanetriol, Glycerol |

|

Packaging |

: Flexi Bag, 23 MT/20 FCL |

.webp)